Ian Linton’s Arnott supercharged TA

The ‘boy racer’ TA

I bought my TA in the mid-sixties for £45 under Brixton Railway Arches. It was a bit of a wreck, but running. Most weekends I worked on it in my parent’s drive so it would be ready to go by Monday morning. My holiday job often involved travelling throughout England and Wales to work on various airfields, so reliable transport was required. The UK MOT test only came out the following year so I got away with many running fixes during the first year.

The car as bought had lots of evidence of being a ‘boy racer’ – BRG, 16” rear wheels, chequered radiator, air horns (now illegal), larger fog lamp and Triumph Herald seats. Being an impecunious student at the time I loved it although it was pretty worn out in all areas. So it was stored away for 30+ years in various locations until I started the restoration around 2000. I rather liked the ‘boy racer’ element so decided to use that as my theme for restoration, rather than the ‘as left the factory’ approach favoured by many others. So it is still BRG with a chequered grill, 16” wheels & tyres, aero-screens added, etc. but in nearly all other respects still remains faithful to 1939 factory output.

I have been very pleased with the result but always felt it was a bit of a sheep in wolf’s clothing. A very long time ago I fitted a Shorrock blower to a little frog-eye Austin Healey Sprite and was delighted at the increase in performance. But not so pleased at the alarming increase in petrol consumption and high rate of wear of the big ends.

Period photo of an early TA Arnott installation

So a couple of years ago I started looking at adding a blower to my MG TA, against all conventional wisdom for an MPJG of course – frail engine, non-counterbalanced crank, etc. Nevertheless I decided a ‘soft’ (low-pressure) system was the way to go and Arnott made a 1600 model about the same time as the car was made. Of course I did not know for sure that such a unit could be squeezed into a TA but was encouraged by a period photo which showed that it had been done at least once. That car still exists but now has an XPAG power unit.

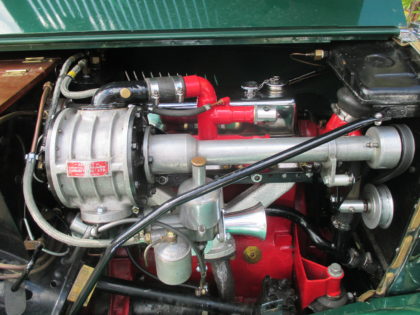

Final setup of Arnott supercharger in my TA

After a search I was pointed to an Arnott unit that had been on a TD, with a complete kit of parts. However as readers will know, an MPJG is very different in detail from an XPAG, especially around the intake and exhaust manifold areas. So none of the kit parts fitted. Lots of trial and error and I eventually worked out a way to fit the supercharger using the existing mounting studs for the original twin carb setup.

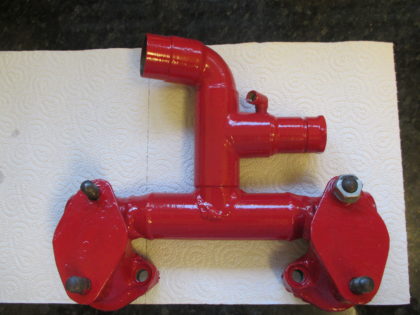

The completed modified inlet manifold

The final set-up is shown above. Of course the inlet manifold had to be highly modified (shown on right) and this was done partly by a local welder and the upper bits by myself using standard end-feed copper fittings (53-22mm diameter), plus a Shorrock-style blow-off valve set at 5psi.

Oil feed to the blower is from a bulkhead mounted oil tank, pressurised from near the blower exhaust port, and metered through a needle valve.

Bulkhead mounted oil tank and feed

The flexible pipes are pvc lined and Arnott instructions were most insistent they not be changed so this area is somewhat tight.

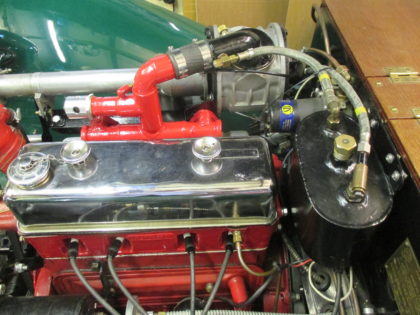

Pulley arrangements

A new crankshaft pulley was required (shown on right) so I stuck to the same belt geometry as for the dynamo belt which worked out well as:

- – only one size up of belt was required, although I changed to the cogged variety

- – using only one belt leaves space in front of the crank pulley to change either dynamo or blower belt creates more clearance for the MGB fan which I have been using successfully since the restoration.

I did have to space the fan further forward slightly with nuts and longer bolting, but so far so good.

As to the cylinder head I was reluctant to risk possible damage to my original (now lead-free) MPJG head so converted a Morris MPJM to late MPJG spec (triple valve springs, lead-free, etc). This is virtually identical except 0.080” thicker so the combustion ratio is already reduced to suit a blower application and enabled me to use a single MPJG head gasket.

I had expected that the thermostat bypass line would get in the way and had all sorts of plans to remove or divert it, but in the end there is just room. As a precaution I have added a rubber sleeve around the bypass pipe as the blower idler pulley shaft pushes against it (although it does not rotate at this point).

The only original MG parts ‘harmed” were one intake manifold (luckily I had three) and part of the web supporting the radiator header tank, being cut back to give room for the driven pulley and belt removal (by also removing the driven pulley).

Difficulties encountered included:

- – having no example installation to follow

- – relative dimensions therefore mostly guesswork

- – making brackets to suit, usually involving three attempts each to get it right

- – ensuring adequate clearances everywhere, but particularly at bonnet side and top, and up front between drive belts & fan, etc

The float bowl was the most difficult after the blower mounting because it and the carb had to stay level but be tucked right in to avoid the bonnet side. This required delicate adjustments to the blower intake, the mating surfaces of the bowl to the carb body, etc. The end result is that the carb top is tucked close under the blower shaft extension, with barely 1/8” clearance of the bowl from the bonnet side.

Then tuning. It has taken quite a lot of trial and error to get the engine running satisfactorily. The 1 3/8” SU that came with it had odd metal blistering to the piston and had to be carefully filed and finished so it was clear running. The internal piston damper was very slightly bent but was easily straightened once the problem was identified. And of course the float had some fuel inside it so had to be replaced. The lid and details were replaced entirely. Lots of problems with petrol leaking from the main jet but eventually solved with o-rings in place of cork. The choke arrangement had to be reworked as it is now 90 degrees from the original and would have fouled the bonnet side. Even so I had to cut the support bracket and brass lever back by ½” to clear the side, and now use the slow-running control to operate it.

Using advice from Arnott literature I wired up the distributor weights to fix them, and will find a better (reversible) method to do this in time, but not now. The distributor seems to be in about the right place, again by trial and error, and the micrometer is at zero so I can experiment each way.

The carb needle has been the biggest single tuning issue. The needle that came in the carb turned out to be almost the same as the ones in performance in my twin carbs and proved to be hopeless, back-firing, blowing the relief valve, struggling to get past 2000 revs, and so on. The richest needles I had in my parts bin improved things slightly, so I borrowed the richest needle I could find and bingo! Full rev range available, no more popping and banging, starts easily, etc. The colour of the spark plugs looks about right, at 1.5 turns of the mixture adjusting nut down, as Arnott recommended.

So how does it go? All I can say is WOW! Plenty of acceleration due to the extra torque but of course no increase in overall speed. However that was not my target. Apart from aesthetics I wanted to keep up with modern traffic a bit better but most importantly to climb long steep hills without impeding traffic. My local ‘test’ hill is about a mile long and gets steeper. With twin carbs and driver only the car would struggle to maintain 40 mph, this on a 70mph dual carriageway, and thus created high differential speeds. First test with the blower installed and it sailed up easily at 55mph, far better. I would have been very happy at 50mph but this really exceeded my expectations.

Longer term testing continues but I don’t plan to alter much at all for awhile yet, as the car is just so much more fun now.

Lastly my thanks to the following MG TA stalwarts who have continued to encourage me in my efforts to achieve the (almost) unachievable despite the onset of serious illness:

Stewart Penfound, Bill Davis, Brian Rainbow and Tim Parrott.

Now the wolf is back in wolf’s clothing.

Ian Linton

19 August 2017

This article was originally published in ‘Totally T-type 2’ www.ttypes.org/ttt2 (Issue 44 published in September 2017)