Reproduction in whole or in part of any article published on this website is prohibited without written permission of The MG Car Club.

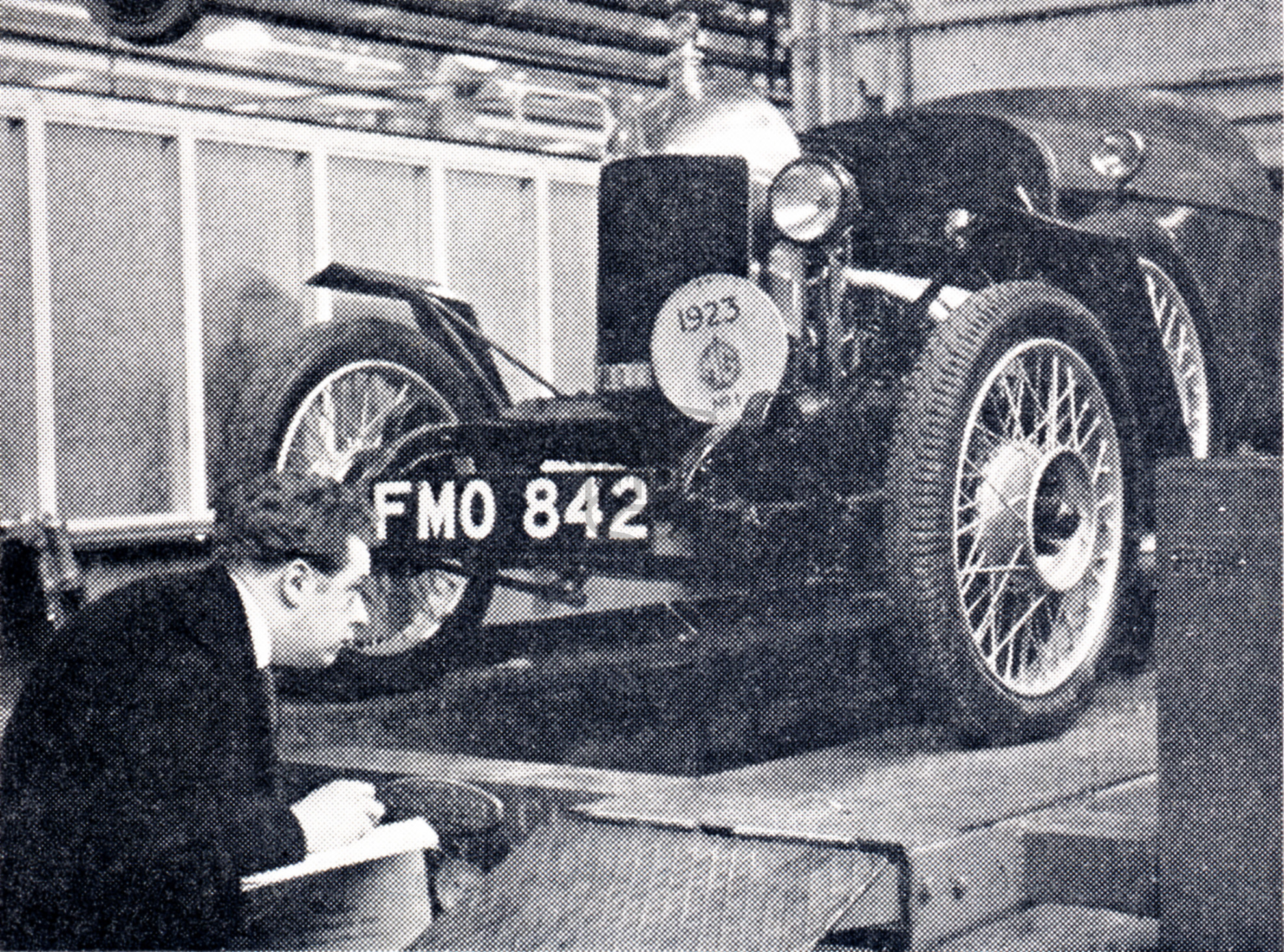

Old Number One

John Thornley tells the story of the first of the line-the two-seater Morris Oxford special that inspired the MG sports car.

However wide the variety of vehicles on the market, there are always some people who want something different from anything currently available. What is more, they are prepared to pay for their idiosyn-crasies, their fun, or their folly—whichever way you care to look at it. Prior to the First World War, quantity production of motor vehicles, in the generally accepted sense of the term, was in its infancy. Hands were used far more than machines in their construction and almost every car was custom-built—in the best sense of that term, too.

Subsequently, with Henry Ford in America and William Morris in England, quantity production got into its stride and the successive products off each assembly line were as like as peas in a pod.

In the city of Oxford, on the outskirts of which William Morris had his factory, the Morris Garages Ltd., one of his selling organizations, sensed almost immediately the demand, created largely by the undergraduates of the university, for this something different. As early as 1922 they were buying Morris chassis from the car-manufacturing plant five miles down the road and mounting upon them special bodies of their own design, built by specialist coachbuilders.

The leading light and driving force in all this was the then Sales Manager, the late Cecil Kimber, under whose guidance numerous designs made their appearance, one of which was particularly popular and known as the ‘Chummy’. This had two normal seats in front, with two very-much-close-coupled seats behind, with the advantage, very uncommon at the time, that a collapsible hood could be erected covering all seats, the normal tendency of the day being to leave the occupants of occasional or ‘dickey’ seats out in the cold. But at the London Motor Show of 1924 Morris Motors, as vehicle manufacturers, introduced a similar body into their standard range, known as the ‘Occasional Four’, and at a lesser price than that which Morris Garages were charging for the ‘Chummy’.

This was an event of great significance. It upset the Garages’ calculations quite a bit, and caused them to re-assess the whole position. From this emerged the principle that specialized design of bodies was not enough, and that, if ‘specials’ were to continue to find a market, chassis changes would also have to be made to provide enhanced performance. So it can truly be said that it was this event more than any other which forced Morris Garages into the sports-car business.

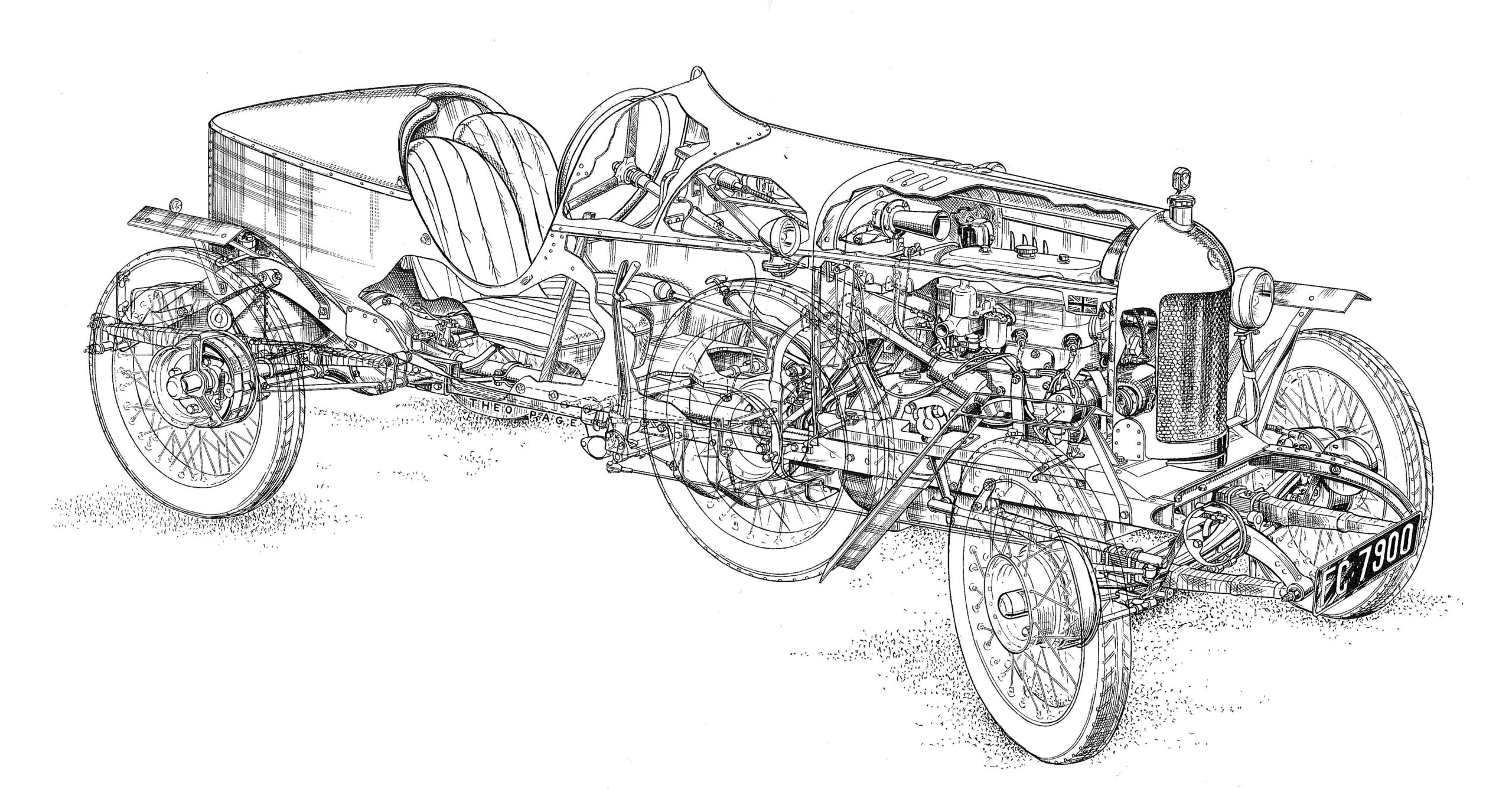

Morris cars currently used an engine of American design, which had been developed by the Hotchkiss Company of France in the English factory they had set up during the war. In the course of early development some engines had been produced with push- rod-operated overhead valves, and Cecil Kimber found one in an almost-forgotten corner of the engines factory in Coventry; he brought it to Oxford in triumph and set about the design and building of the car which Theo Page, of Autosport, has drawn for this first issue of ‘SAFETY FAST’.

The engine has four cylinders in line with a bore of 695 mm. and a stroke of 102 mm., giving a swept volume of 1547 c.c. The camshaft, low down in the cylinder block on the left-hand side, is driven by steel and bronze helical gears and operates the valves, also in line, through tappets, tubular push-rods, and rockers. Valves are small by present-day standards, but have double springs. An eccentric in the centre of the camshaft operates a vertical plunger oil pump (of somewhat larger capacity than the standard pump of the day) which feeds the main bearings under pressure through a gallery pipe. Big-end bearings are splash-fed. A bleed from the front bearing leads to an externally adjustable needle valve, which controls the quantity of oil fed to the valve gear through a hollow rocker shaft.

The original carburetter has been lost, but was an early S.U. A modern version of the same make, with a choke diameter of 1 ¼ in., has taken its place. Fuel feed is by air pressure, a hand pump, with pressure gauge, in the cockpit providing up to 6 lb./sq. in. in the rear-mounted fuel tank.

The clutch has a single driven plate with cork inserts running in oil in a single unit with an orthodox three-speed and reverse ‘crash’-type gearbox. The transmission shaft is enclosed in a torque tube articulated through a massive spherical joint on the rear gearbox cover, and feeds a spiral bevel final drive of 12 : 53 ratio.

The frame side-members are of box section, parallel in plan view and substantially straight in elevation except where they sweep up over the rear axle. The engine has very substantial four-point mountings, and is bolted firmly into the frame, which makes the whole structure very solid from the gearbox forward. By contrast the aft end of the frame is left torsionally supple to assist suspension deflection, the body and brake gear being mounted in such a way as to permit distortion without adverse effects.

Ignition is by magneto, which lies athwart the front of the engine, being driven by a skew gear from the top of the camshaft gear. An external pulley on the front of the camshaft drives, through a Whittle belt, the 6-volt dynamo and the tachometer drive. No electric starter is provided, but a starting-handle is a permanent installation in a long bearing cast integral with the oil base.

This method was successfully followed in the ‘J, ‘K’, ‘P, and ‘T’ series of cars right up to the advent of independent front suspension. That in the case of Old Number One it was, to say the least, somewhat overdone is indicated by the fact that, during early tests, the frame broke in halves immediately aft of the rear engine mounting. The plates by which it was repaired and reinforced remain to this day.

The front axle is an orthodox beam, giving a track of 48 in., mounted on stiff leaf springs damped by ‘Gabriel Snubbers’. These were the popular shock absorbers of the time, consisting of a coil of woven belting housed in a drum bolted to the frame, the free end of the belt being pulled tight and attached to the axle. A moment’s consideration will show that these offer no resistance on bump, but a progressively increasing damping action on rebound— so they had a great deal to be said for them.

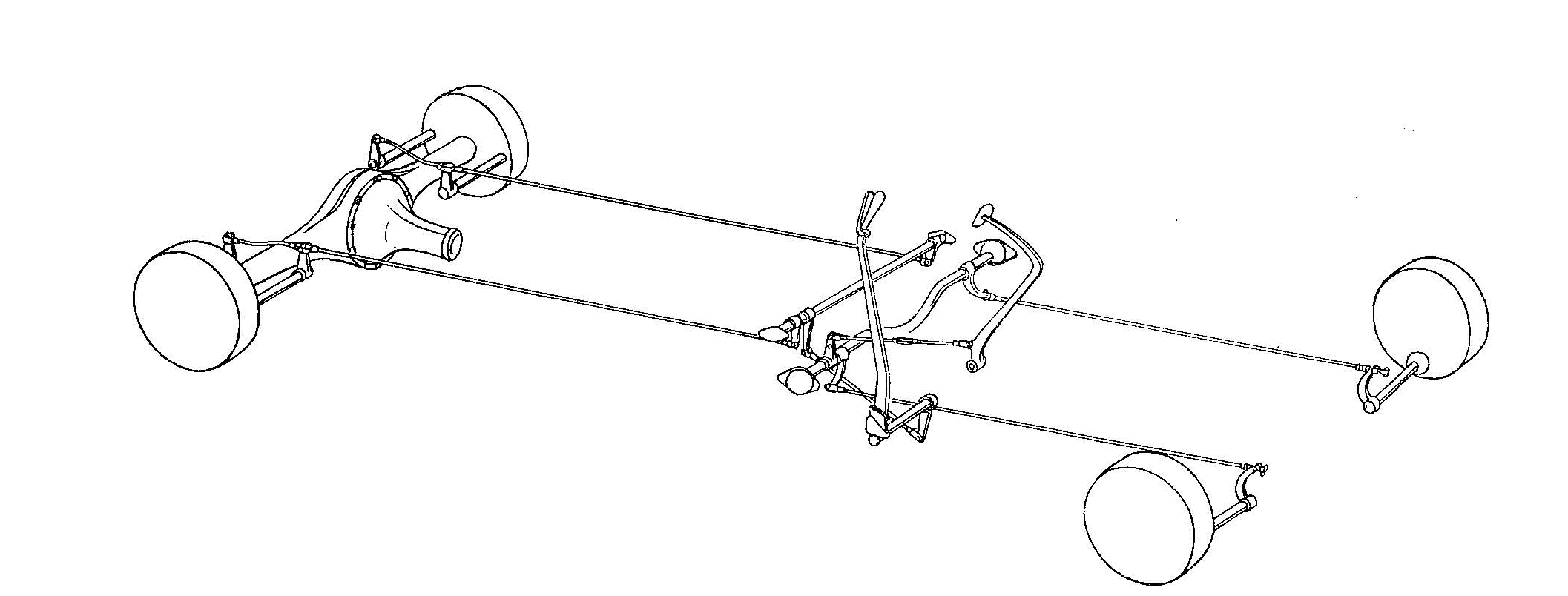

The braking system has several interesting features. As originally designed for the Morris Oxford, the foot brake operated on all four wheels, but each rear drum contained two pairs of shoes, one pair of which was coupled to the foot brake and the other to the hand brake which was little more than a parking brake. On the MG the foot brake operated only the front brakes, the hand brake a substantial lever outside the body (very sporting!)— working the rears. By an ingenious coupling linkage this hand brake operated all eight rear shoes in such a manner that four of them were leading and four trailing. This was one of the earliest applications of 2 LS.

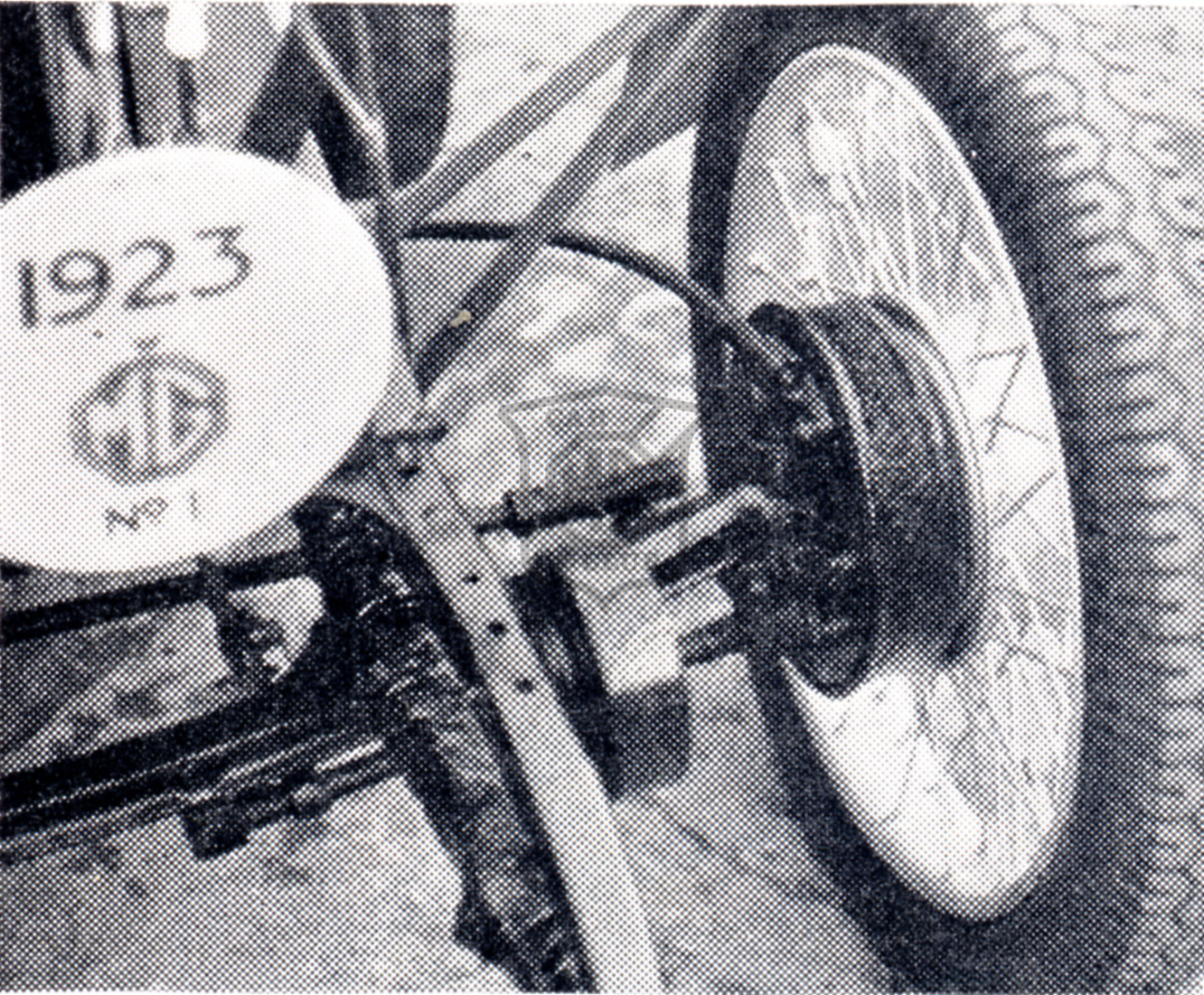

The rear axle is mounted on leaf springs with pendent shackles at each end and damped by double-action Hartford shock absorbers. The final drive is distinctly massive, but the axle construction is such that axle shaft and rear hub bearing must be removed in order to get a brake-drum off. Wire-spoked wheels secured by three studs carry 7.10—90 tyres, the rims being fitted with balance weights opposite the tyre valves.

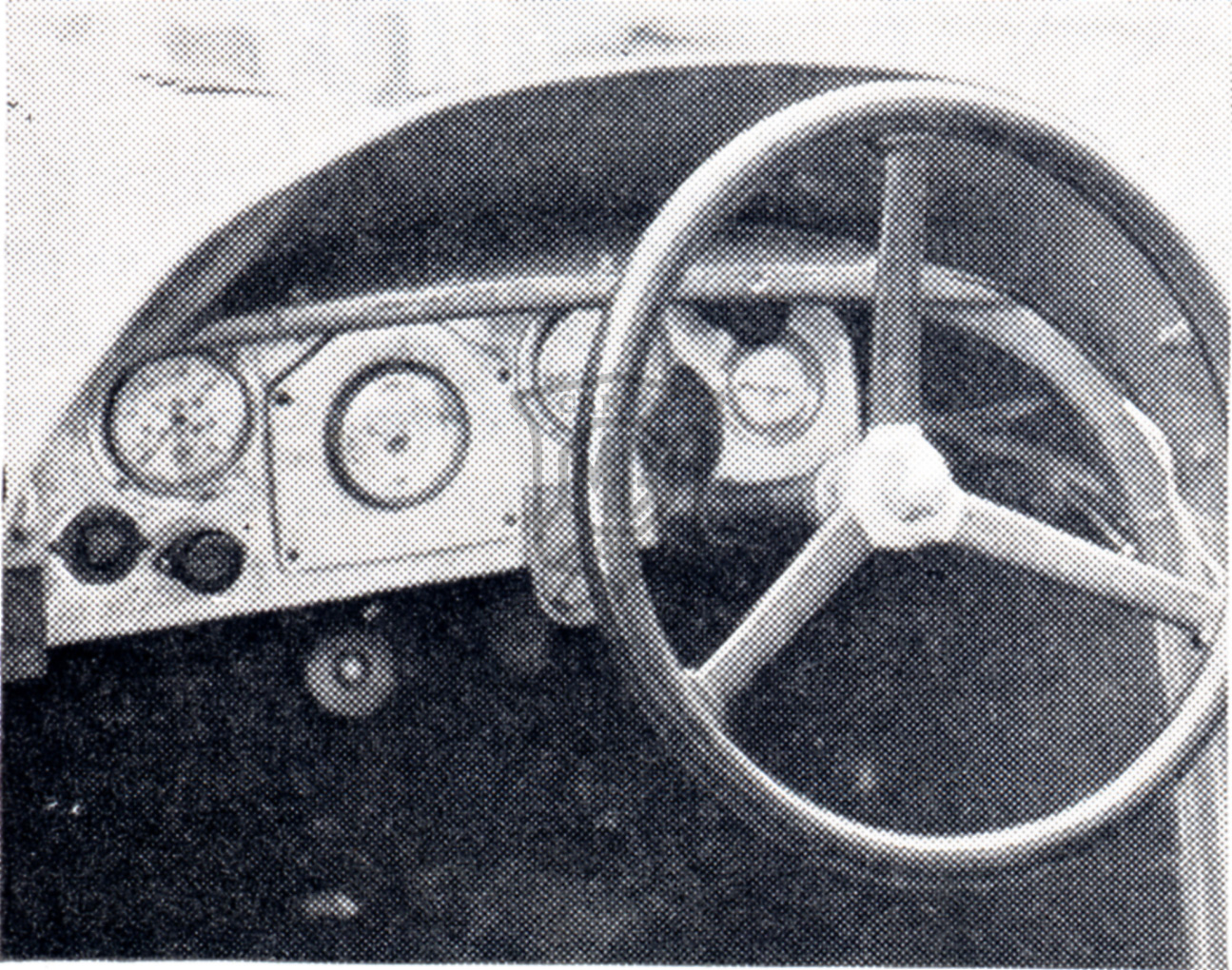

Instruments are few but practical. The combined speedometer and odometer is driven by cable from the left front wheel, and the engine speed indicator by cable from the belt-driven pulley already mentioned. Oil pressure gauge, ammeter, and fuel tank pressure gauge complete the instrumentation, while controls consist of a horn-push, a mixture control, and a light switch operated by rotating the bezel of the ammeter.

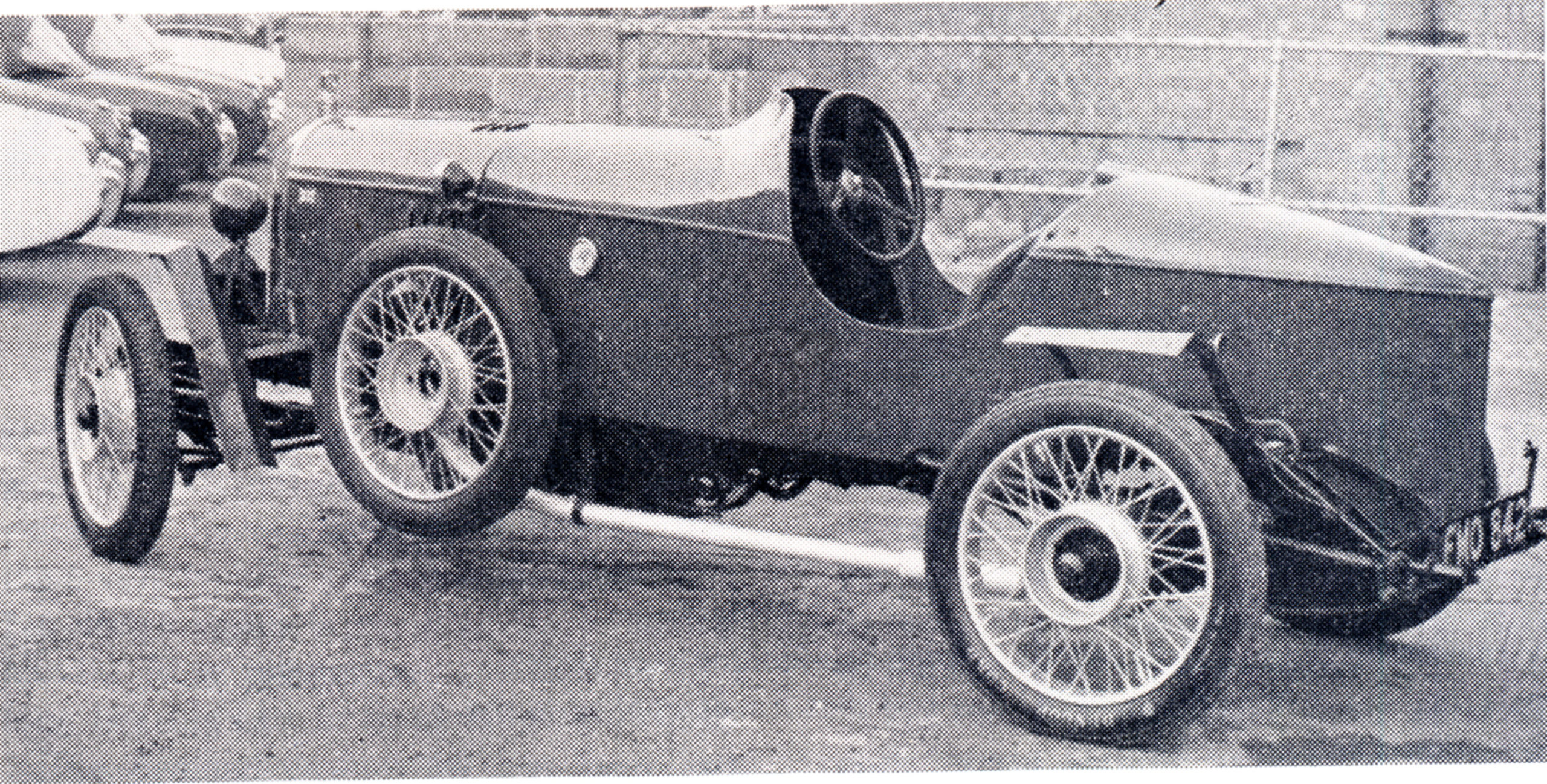

Body and wings are rudimentary in the extreme, no windscreen or hood being provided. To reduce body width the two seats are set echelon fashion, and the total width at the shoulders is 33 in.

This machine was running before the end of 1924, and our picture shows it being driven by Cecil Kimber in the London/Lands End Trial of 1925, securing a Gold Medal. Though the radiator bore, and still bears, the Morris Garages medallion, the caption to the picture in The Motor of that time referred to it as an MG It was not until two years later that the now-familiar MG octagonal motif appeared on the radiator of Morris Garages’ products, but there can be no doubt that Old Number One is justly regarded as the first of the line.

To carry this story a little further, an inevitable event which was to affect MG history in a manner out of all proportion to its importance should be recorded. One of the salesmen at Morris Garages attained his twenty-first birthday. This was GS Gardiner, and his birthday brought with it a small ‘bag of gold’, with which he intended to realize a youthful ambition and own a car designed to his own requirements. These he sketched to his then chief, Cecil Kimber, who seized the opportunity to utilize this special order as a means of producing a prototype for his next production body. This, allied to chassis features derived from Old Number One gave rise to the series of vehicles which came to be known as the MG Mark IV, the popularity of which provoked a quest for new and larger premises and led to the formation of The MG Car Co. Ltd. on the site it now occupies at Abingdon.

Those who wish may pursue this story in Maintaining the Breed, the Saga of MG Racing Cars, by John Thornley, published by Motor Racing Publications, London.

the ‘Old Gang’

CECIL COUSINS: Joined Morris Garages Ltd. as a fitter in the Motorcycle Shop in 1920. Associated with the production of the ‘specials’ from the earliest days. Now WORKS MANAGER of The MG Car Co. Ltd.

SYDNEY ENEVER: Joined the Garages as a shop boy in 1920. Became a fitter in the Repair Shop, then transferred to Experimental Department, Abingdon. Now CHIEF ENGINEER. Designer of the ‘MGA’.

JACK GARDINER: Joined the Garages as salesman in 1921. After a spell in the Royal Air Force returned to MG and is now PERSONNEL MANAGER.

JACK LOWNDES: Joined the Garages in 1923 as electrician in Vehicle Assembly. Now WORKS ENGINEER.

CHARLES MARTIN: Joined the Garages in 1921 as assistant in the Machine Shop, where he helped to build Old Number One. Now head of PROGRESS DEPARTMENT.

GEORGE MORRIS: Joined the Garages as a fitter in 1918. Assisted in the assembly of early ‘specials’, then became Chief Tester. Now SUPERINTENDENT, ‘B’ BLOCK (Rectification and Finishing).

STAN SAUNDERS: Joined the Garages to assist Cousins in 1923. Later i/c Tool Stores. Now assists Charles Martin in PROGRESS DEPARTMENT.

FRANK STEVENS: Foreman, Morris Garages Machine Shop, 1923, where he was responsible for assembly of Old Number One. Retired this year from The MG Car Co. Ltd. as CHIEF PROCESS PLANNER.

(Cecil Kimber could certainly pick ‘em.)

MG Car Club

MG Car Club