So You Want To Buy An MGC?

Introduction

So you want to buy an MGC? And indeed, why not? When the model was introduced at the 1967 Earls Court Motor Show, it was the most powerful MG sports car ever built. With a new 2912cc (3 litre) straight six-cylinder engine, this was a ‘true’ Grand Tourer in every sense of the word. From the launch of the MGB in 1962, there was always meant to be a more powerful version and it was only a matter of time before a suitable ‘big’ engine was developed and fitted.

The MGC was developed during a politically-charged era of British motor industry history when rationalisation was the ‘buzzword’ and financial expediency held more sway than consumer satisfaction. So the MGC was born into a world of industrial uncertainty and one where the British motoring Press acted like theatre critics with the clout to make, or usually break, an innovative model at the stroke of a chewed pen top.

Stories abound of ‘Press’ cars being left in crumpled heaps having failed to negotiate bends and of lack of acceleration power to ‘get out of trouble’. Tales also proliferate of poor handling and slow steering. The new engine was, after all, 209lbs heavier than the MGB’s 1798cc B-Series engine and it is true that the weight distribution in the MGC was different from that of the MGB being 55.7%/44.3% for the MGC as opposed to 52.5%/47.5% for the MGB, thus making the MGC ‘nose heavy’ with much of the weight forward of the front wheels.

This uneven load allocation led to a degree of ‘understeer’, which when combined with the legendary reports of the tyres on the Press cars being under-inflated, compounded the issue. Incidentally, Dunlop SP41 tyres (as fitted to the MGB) were initially chosen for the MGC, a decision that was to prove costly in terms of poor handling and resulting reputation. Parables of MGCs driven into bends faster than MGBs would have been driven, and by the same Journalist, presumably blissfully unaware of his speed due to the smooth, understressed nature of the new engine, never cease to amaze me. Had they never thought to look at the speedometer?

Many of the problems associated with the MGC could, would and should have been sorted out prior to the model’s launch had Abingdon been given the appropriate development time. It is easy to say, with hindsight, that the MGC was much maligned and that, with the use of today’s technology and innovative product materials, the car can be vastly improved. This can be seen in many of the remaining examples still in use today, 40 years after the model’s first introduction!

Model History

The Austin Healey 3000, also assembled at the Abingdon factory, was fast coming to the end of its production and would be phased out by the end of 1967, so the race was on to find an engine powerful enough to perpetuate the British sports car tradition, especially in the lucrative North American market.

As well as being a replacement for the Austin Healey 3000, the MGC was intended as an ‘MGB with muscle’. Rationalisation within the BMC Group meant that, as far as possible, the same monocoque body shell could be fitted with a number of engine derivatives.

A number of power plants were considered including a 2.6 Litre four-cylinder engine and a 2433cc straight six-cylinder unit used in Australia for heavy goods vehicles (it is surprising just how many people seem to remember this little known engine and firmly associate it with the MGC).

The final choice of engine for the MGC, however, dictated that many structural alterations had to be made to the existing body shell in order to facilitate fitting the heavier and taller ‘lump’ than was at first anticipated. These alterations visually manifested themselves in the longitudinal bonnet bulge, which allowed the radiator to be moved forward and up tight against the bonnet locking panel, and the ‘teardrop’ prominence on the left-hand side of the bonnet to clear the forward carburettor.

Opening the bonnet, further distinctive changes are obvious, with the removable cross-member on which the MGB’s suspension and steering was mounted being replaced by extensions to the inner wing arches which effectively created a new, built-in U-shaped cross-member, greatly strengthening the bodyshell.

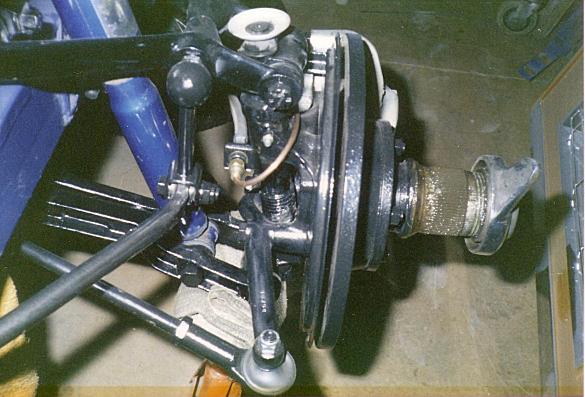

The engine bay was not the only alteration necessitated by the newly developed MGC engine. A completely new front suspension layout was needed to replace the coil-spring and lever-arm damper setup which was an integral part of the MGB cross-member. The MGC used a combination of upper wishbones and parallel lower arms, now secured to the inner wing panels and cross-member respectively, damped by telescopic shock absorbers and sprung via torsion-bars running longitudinally to adjustable securing points under the front seats, sited within a new triangular box section.

During the MGCs short production run, a total of 8,999 cars came off the assembly line with a slightly larger proportion of Roadsters (4,542) than GTs (4,457). Of these total production figures, 3,437 were built for the Home Market (1,405 Roadsters/2030 GTs) while 4,256 were export specification models destined for the North American Market.

The MGC boasted a top speed of 120mph and 0–60mph in 10.0sec. The MGC speedometer displayed a theoretical top speed of 140mph, this being one of the few cockpit differences between the MGB and MGC.

The engine finally developed for the MGC was different from the original BMC C-Series as it now had 7 main bearings rather than 5 and was 1¾ inches shorter. The official power output figure for the engine installed in the MGC was given as 145bhp at 5,250rpm, with a torque figure of 170lbft at 3,400rpm. These figures were slightly less than those for the Austin Healey 3000 which it was due to replace, data which the motoring press were only too keen to publicise. The addition of the extra bearings was, whilst making for a stronger, smoother and more reliable unit, one of the main reasons for the reduction in power through increased friction and windage within the engine.

University Motors, one of BMC’s main London dealerships, is widely known to have produced a number of ‘specials’, with no two cars being the same. These were usually prepared to individual customer’s requirements and many included special paint combinations, a wood-rim Motolita steering wheel, Koni dampers fitted all around, Cosmic or J A Pearce alloy wheels or a different stage of tuning and interior. Many of University Motors ‘specials’ carried a round enamel badge on the bonnet forward of the radiator bulge and a rectangular enamel plaque on the dashboard.

Collaboration between University Motors and Downton Engineering Ltd led to the production of an option of three ‘stage tuned’ MGC conversions, which were produced with the full agreement of Abingdon and maintained the Factory Warranty.

The most desirable of the Downton tuned MGCs were those with the Stage 2 (Number 43 Conversion). This model kept the twin carburettors although a modified, ported cylinder head was substituted. A re-profiled, polished inlet manifold and twin, tubular exhaust manifolds were fitted, these outputting to a twin exhaust system.

Although the Stage 2 Conversion gave only a 9bhp increase over the standard factory figures, Downton’s performance figures showed a dramatic improvement. Could the factory’s figures have been wrong, given that there was no apparent independent verification of Abingdon’s performance figures? A few, rare Downton MGC’s were fitted with triple Weber DCOE twin-choke carburettors. Remember that this was a time when petrol was relatively inexpensive!

It is important to note that reproductions of University Motors and Downton enamel badges and stickers are plentiful on the Internet and that not all MGCs purporting to be ‘Specials’ are original! You would be well advised to seek the help of an expert on these models when considering the purchase of any MGC offered for sale as a UM or Downton car.

Model Differences

A new gearbox was developed for the MGC with synchromesh on all forward gears and with a higher torque capacity. There were to be a couple of changes to the gear ratios during the model’s short production run and a customer could specify a Laycock overdrive unit as an optional extra, giving overdrive selection in third and top gears. A Borg Warner Type 35 automatic transmission was also offered as an option on both the MGC Roadster and GT models.

At launch, the MGC was offered with a Manual gearbox whose ratios were: (4th Gear) 1.00, (3rd Gear) 1.382, (2nd Gear) 2,167, (1st Gear) 3.44, (Reverse) 3.095. With the Laycock overdrive specified the following gearbox ratios applied: (4th Gear overdrive) 0.82, (4th Gear) 1.00, (3rd Gear overdrive) 1.07, (3rd Gear) 1.307, (2nd Gear) 2.058, (1st Gear) 2.98, (Reverse) 2.679). Gearbox ratios were to later change for the 1969 year, non-overdrive model, giving: (4th Gear) 1.00, (3rd Gear) 1.307, (2nd Gear) 2,058, (1st Gear) 2.98, (Reverse) 2.679.

Unlike the MGB which, up to the launch of the MGC, was fitted with the ‘banjo’ type rear axle, the much stronger Salisbury axle was the final drive of choice for the MGC. Early production non-overdrive models were fitted with a ratio of 3.07:1. Models fitted with the Laycock overdrive unit and also those where the Borg Warner Automatic transmission was specified had a rear axle ratio of 3.31:1.

On later models fitted with the overdrive unit (Tourers from chassis number 4,236 and GTs from chassis number 4266) the axle ratio changed once again to 3.7:1.

Spares Availability

Apart from a handful of items, the majority of the MGC is easily replaceable. As the years roll by, more specialists and parts suppliers have commissioned the remanufacture of pattern parts to quell enthusiasts’ demands to keep their MGCs running. This situation obviously negates the need to dismantle existing cars and increases the opportunity to ‘save’ yet another MGC from the ‘breaker’s yard in the sky’! The downside to this parts proliferation is that production quality, especially from the Far-East is less than might be expected and, in some instances, downright shoddy and unacceptable. The moral must therefore be caveat emptor.

As already stated, the MGC shares much in common with the MGB. Most external body panels are available as ‘patterns’ and, better still, many are also available through selected British Motor Heritage outlets, these panels having been pressed from the original dies that were salvaged when Abingdon closed. Some of the major players in the spares and repair business are Brown & Gammons (Hertfordshire), Beech Hill Garage (Reading), Moss Europe Ltd (Nationwide outlets), The MGB Hive Ltd (Wisbech, Cambs.) and MG Motorsport (Hertfordshire).

Doug Smith of MG Motorsport, who is widely thought of as one of the two ‘guru’s’ of the MGC world (the other being Vic Young of Coulsden, Surrey, race advisor to the MGC Register), has developed an excellent reputation for the restoration, servicing and specialist tuning of the model. After many years racing MGCs, Doug has also developed several upgrades to suspension, steering and handling for both road and competition use.

What to look for

There is a wealth of information available to the MG enthusiast seeking a suitable car to buy. The Internet provides a number of enthusiast’s Bulletin Boards (eg the BBS forum which can be found at www.mgcars.org.uk) where information can be shared and an individual’s mechanical or technical problem can often be solved by ‘posting’ a simple question. Remember that the Internet has a world-wide participation and the wealth of knowledge available is therefore immense.

Both the MG Car Club and the MG Owner’s Club provide ‘guidance notes’ for anyone seeking information on purchasing an MG and the MG Car Club’s MGC Register is a particular source for anyone looking for this precise model.

It is pertinent to mention Lindsay Porter’s excellent book, ‘A Guide to Purchase & DIY Restoration of the MGB’. Published by Haynes Publishing Group, this book lists particularly important areas to inspect when viewing a possible MGB or MGC to purchase.

Sharing such a large percentage of its body shell design with the MGB, it is inevitable that the dreaded ‘metal worm’ finds the MGC just as delectable a meal as its lesser powered brother. Subsequently, the areas of concern to a prospective purchaser will be very similar. It must be made clear that although the MGB and MGC Roadster and GT bodies look identical (apart from the bonnet), the underside from the front seats forward, and the inner front wings bear no relationship to one another. This should be considered when structural repairs are required as replacement panels are unobtainable.

To summarise, the significant areas when scrutinising an MGC are:

All panel edges, especially doors, boot lid, footwells, boot floor and corners, battery boxes and wheel arches etc. should be checked for signs of rust. Pay particular attention to ‘panel fit’, i.e. are the gaps even all around?

Notable areas for rust are around the front headlamps and sidelight clusters. As a rule, beware of any sub-paint bubbling – it is a fair indication of future work to be done or the result of a previous attempt to disguise potentially expensive remedial work.

The majority of MGC bonnets were made of aluminium, which although not susceptible to rust, does oxidise if left unpainted and is prone to dents from stones and inconsiderate owners! Replacement aluminium bonnets are extremely expensive (if you can find one!) and some may have been substituted with steel versions. There is evidence that some of the last MGCs produced may have had steel bonnets fitted from new, and these will need to be checked for signs of rust.

The transverse decorative stainless steel bonnet strip may sometimes cause galvanic corrosion with the aluminium bonnet where the retaining bolts are situated. This does not usually result in serious damage if caught early, but is worth considering when paying ‘top dollar’ for an MGC.

Signs of blistering under the paint around the fillet strips fitted to where the front wings mate with scuttle panel and also to the top edge of the rear wings usually indicate future problems and, in the case of the front wings, major remedial work will almost certainly be required underneath.

The turret box sections to the top rear of the front wings (checked by turning wheels and pushing hand up to top of front wing under the wheel arch – dirty work!) are a notorious area for corrosion through a build up of road dirt and silt thrown up by the front wheels. Corrosion here can, if left unattended, stretch further back to the A posts.

Pay particular attention to the under floor triangular box section which the Torsion-bars pass through. These are not currently available.

Front Torsion Bar, telescopic damper and Kingpin suspension set-up is very strong on the MGC and does not usually cause problems. However, regular maintenance and greasing of the kingpins will greatly reduce wear and avoid failure.

The engine and gearbox fitted to the MGC are rarely a cause for concern due to the ‘laid back’ attitude of the very strong 3 litre engine. Regular servicing is advisable and, although a well maintained C engine will easily cover over 150,000 without trouble, many cars around today will have had their ‘power plant’ rebuilt, usually when a ground-up restoration has been carried out.

And most important of all – the sills. Because the strength of the monocoque body shell is dependent on the box sections running between the front and rear wheel arches being sound, this area should be scrutinised as if your life depended on it – because it does!

The sill section comprises: the outer sill (the curved part you see from the outside below the doors); the inner sill (the right-angled rubber mat/carpet covered section inside the cockpit running parallel to the seats); a vertical closing panel (welded between the inner and outer sill sections) and the ‘castle rail’ (a horizontal panel running underneath the length of the sill).

Rust in these vital areas usually only becomes apparent when bubbles start to appear on the outer sill, usually at the forward end. By this time rust damage has almost certainly been done to the closing panel and in the later stages of sill corrosion, perforation of the inner sill will also result. The only remedy is for complete sill replacement which can be very expensive.

Significantly, an MGC in good, original condition and to original specification will tend to command a higher price than a modified specimen – for obvious reasons.

Painted 15” diameter centre-lock wire wheels or 5-stud pressed steel wheels with chrome wheel disc trims were factory fitted. A 16½” diameter, leather clad steering wheel graced the driver’s view and the speedometer read 140mph – very impressive for those days!

Footwell mats, inner sills and driver’s foot-rest coverings were originally rubber, although many of these will have perished over the years and may have been replaced with carpet where ‘as original’ replacements have been difficult to source.

Recommendations

As with all classic cars, it is worth every minute of the prospective buyer’s time spent researching the model in which they are principally interested before actually parting with hard earned cash. This will save £’s in the long term and may even sow seeds of doubt as to the suitability of a particular car for your purposes.

At the risk of repetition, a search of the Internet for owner’s views is invaluable. Visit the BBS Forum and ask questions – don’t be afraid to ask seemingly undemanding queries – you will be amazed how friendly MGC owners are and willing to help a ‘rookie’!

Beg, borrow or steal (not literally!) as many books as you can find on the subject. The following are just a small selection of enlightening books containing valuable and useful information on the MGC:

‘The MGA, MGB and MGC’ by Graham Robson

‘A Guide to Purchase & DIY Restoration of the MGB’ by Lindsay Porter

‘Original MGB with MGC and MGB GT V8’ by Anders Ditlev Clausager

‘The Mighty MGs’ by Graham Robson

‘MGC – Abingdon’s Grand Tourer’ by Graham Robson (Out of Print).

Contact the MGC Register of the MG Car Club. They may know of an owner who is planning to sell a vehicle and it is worth mentioning that members of recognised MG clubs are generally more caring of their cars than non-members. The Register may be aware of the particular car you are interested in and have some knowledge of previous owners or the car’s history.

Through the MG clubs, make contact with their area representative within your locale. They have an ‘ear to the ground’ for cars for sale, or potentially for sale.

Unless the soon to be buyer has previous experience of problematical areas on MGB/Cs, seek the assistance of an MG specialist in the area, they will almost certainly be willing to offer knowledge and advice as you are a potential customer of theirs for the future. Failing that, ask another MG owner or friend to accompany you to any viewing. There is usually safety in numbers and two heads are better than one!

MGC – An Owner’s view

This is where it becomes personal – I have owned my MGC Roadster for only two years, although I have owned several MGBs, MGB GTs and an MG TF 1500 since 1976. Like so many other MG owners I was dissuaded from MGC ownership by what I now know to be fictitious, nay malicious, horror stories of atrocious handling, poor fuel consumption, dreadfully slow steering and poor resale value. Oh, joy of joys, have I seen the light?

As outlined above, these were the qualities pontificated by the motoring press at the launch and many criticisms were not too far from the truth. However, with the passage of time, dedicated enthusiasts, parts and tuning specialists have solved the majority of the handling and performance issues to the point where an MGC on the road today is a very different animal to the one displayed at the 1967 Motor Show.

Parabolic springs, SuperFlex suspension bushes, high-ratio steering racks – heavens, power steering units if you so wish! Modern tyre technology, uprated anti-roll bars, gas flowed and ported cylinder heads – the modification options are endless. Each helps make the MGC handle and perform as it should have done when it first left the MG Car Company factory in 1967. The singular criticism that the MGC had ‘lost the Abingdon feel’ is no longer accurate.

My particular car had the engine lightened and balanced in 1991 by the first owner and it had covered only 4,200 miles in 14 years when I acquired it. It is shod with 196x65x15 tyres on 5.5J KN replica Minilite centre-lock alloy wheels and it goes around ‘on rails’.

On a recent trip to the MGC40 Weekend Event and at a constant Motorway cruising speed of 65-70mph, 30.5 mpg was attained and the return journey (cruising at just over the permitted legal limit – honestly!) achieved 28.7 mpg. Usual leisure driving, and I do a lot as my MGC is so pleasurable to drive, the fuel consumption averages 22-24 mpg. Oil pressure is 40psi at 2000rpm and it idles hot at 20psi with the temperature steady between 180° – 190° Fahrenheit.

To be honest, this MGC is the most enjoyable MG I have ever owned. A smile radiates across my face every time I sit in the high-back leather seats I fitted because I wanted just a little more comfort.

My other concessions to modern day travel have been to fit a Hazard Warning Light circuit/switch and a discrete High Level Brake Light that sits on the boot lid.

Should I have bought an MGC before? Perhaps not. Why? Although prices would have been less high, the information from owners and published works on the MGC were not as abundant and there was not the World Wide Web to share problems and solutions.

In Conclusion

Finally, when considering whether or not to buy an MGC, there is an age old saying when seeking to purchase an MG – ‘look at many and don’t buy the first one you see’! A comment easily ‘trotted out’ as one’s heart rules one’s head and MGCs become less abundant as collections are amassed or others broken for spares.

It is always advisable to buy the ‘best original’ example that you can realistically afford.

Should you choose to buy an MGC, I don’t think that you will regret your decision – but then, I might just be a little bit biased . . .

The MGC Register is very grateful to Robert Lynex (MGC Roadster #1100) for his significant contribution to the production of this article. Thanks must also go to Ted and Sally de la Riviere of Beech Hill Garage and Brian Hutchison for their additional input.

MG Car Club

MG Car Club